(→45 nm Microprocessors) |

(fixed) |

||

| (3 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{Lithography processes}} | {{Lithography processes}} | ||

| − | The '''45 nanometer (45 nm) lithography process''' is a [[technology node|full node]] semiconductor manufacturing process following the [[55 nm lithography process|55 nm process]] stopgap. Commercial [[integrated circuit]] manufacturing using 45 nm process began in 2007. This technology was superseded by the [[40 nm lithography process|40 nm | + | The '''45 nanometer (45 nm) lithography process''' is a [[technology node|full node]] semiconductor manufacturing process following the [[55 nm lithography process|55 nm process]] stopgap. |

| + | :Commercial [[integrated circuit]] manufacturing using [[45 nm]] process began in [[2007]]. | ||

| + | This technology was superseded by the [[40 nm lithography process|40 nm]] (HN) / [[32 nm lithography process|32 nm process]] (FN) in [[2010]]. | ||

== Industry == | == Industry == | ||

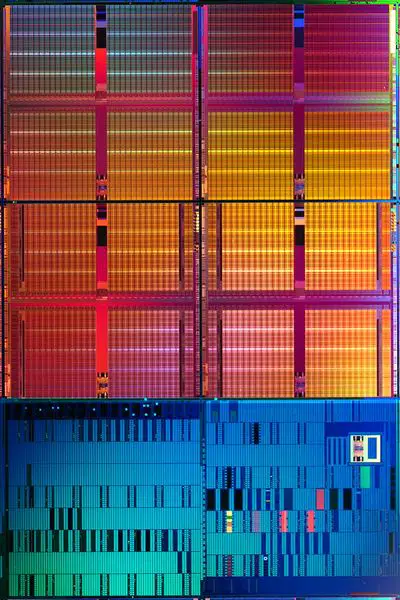

| − | In January of 2006 Intel announced that they've been able to fabricate the first fully functional [[SRAM]] chips on a 45 nm process. As a preview Intel showcased | + | [[File:45nm SRAM photo.JPG|left|400px|Die photo of an [[Intel]] [[45 nm]] shuttle test chip including 153 MiB [[SRAM]] and logic test circuits]] |

| − | {{scrolling table/top|style=text-align: right; | first=Fab | + | In January of [[2006]] [[Intel]] announced that they've been able to fabricate the first fully functional [[SRAM]] chips on a [[45 nm]] process. As a preview Intel showcased 45 nm SRAM chip (shown below) packing more than 1 billion transistors. Intel opened 3 45 nm facilities, their initial {{intel|D1D}} facility in Oregon, {{intel|Fab 32}} in Arizona and {{intel|Fab 28}} in Israel. Intel's 45 nm process is the first time high-k + metal gate transistors was used in high-volume manufacturing process. |

| − | |Process Name | + | |

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! colspan="4" | [[Intel]] 45 nm Design Rules | ||

| + | |- | ||

| + | ! Layer !! Pitch !! Thick !! Aspect <br>Ratio | ||

| + | |- | ||

| + | | Isolation || 200 nm || 200 nm || - | ||

| + | |- | ||

| + | | Contacted <br>Gate || 180 nm || 60 nm || -- | ||

| + | |- | ||

| + | | Metal 1 || 160 nm || 144 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 2 || 160 nm || 144 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 3 || 160 nm || 144 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 4 || 240 nm || 216 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 5 || 280 nm || 252 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 6 || 360 nm || 324 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 7 || 560 nm || 504 nm || 1.7 | ||

| + | |- | ||

| + | | Metal 8 || 810 nm || 720 nm || 1.8 | ||

| + | |- | ||

| + | | Metal 9 || 30.5 µm || 7 µm || 0.4 | ||

| + | |} | ||

| + | |||

| + | === Specifications === | ||

| + | {{scrolling table/top|style=text-align: right; | first=Fab /<br>Manuf | ||

| + | |Process <br>Name | ||

|1st Production | |1st Production | ||

|Type | |Type | ||

| Line 18: | Line 52: | ||

{{scrolling table/mid}} | {{scrolling table/mid}} | ||

|- | |- | ||

| − | ! colspan="2" | [[Intel]] !! colspan="2" | [[Fujitsu]] !! colspan="2" | [[TI]] !! colspan="2" | [[Toshiba]] / [[Sony]] / [[NEC]] !! colspan="2" | [[Samsung]] !! colspan="2" | [[IBM]] / [[Toshiba]] / [[Sony]] / [[AMD]] | + | ! colspan="2" | [[Intel]] !! colspan="2" | [[Fujitsu]] !! colspan="2" | [[TI]] !! colspan="2" | [[Toshiba]] / <br>[[Sony]] / [[NEC]] !! colspan="2" | [[Samsung]] !! colspan="2" | [[IBM]] / [[Toshiba]] / <br>[[Sony]] / [[AMD]] |

|- style="text-align: center;" | |- style="text-align: center;" | ||

| − | | colspan="2" | P1266 (CPU) / | + | | colspan="2" | P1266 (CPU) / P1269 (SoC) <br>/ P1266.8 (SoC) || colspan="2" | CS-300 || colspan="2" | || colspan="2" | || colspan="2" | 11LP || colspan="2" | |

|- style="text-align: center;" | |- style="text-align: center;" | ||

| colspan="2" | 2006 || colspan="2" | 2008 || colspan="2" | 2008 || colspan="2" | 2006 || colspan="2" | 2007 || colspan="2" | 2007 | | colspan="2" | 2006 || colspan="2" | 2008 || colspan="2" | 2008 || colspan="2" | 2006 || colspan="2" | 2007 || colspan="2" | 2007 | ||

| Line 40: | Line 74: | ||

| || || || || || || || || 0.11 µm² || 0.58x || 0.067 µm² || 0.53x | | || || || || || || || || 0.11 µm² || 0.58x || 0.067 µm² || 0.53x | ||

{{scrolling table/end}} | {{scrolling table/end}} | ||

| + | |||

=== Intel === | === Intel === | ||

<gallery widths=200px heights=300px> | <gallery widths=200px heights=300px> | ||

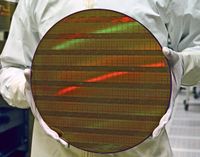

| − | File:45nm | + | File:45nm wafer photo 2.JPG|Intel engineer holding 300 mm wafer with 45 nm shuttle test chips |

| − | |||

File:45nm wafer photo 1.jpg|300 mm wafer with 45 nm shuttle test chips | File:45nm wafer photo 1.jpg|300 mm wafer with 45 nm shuttle test chips | ||

| − | |||

File:45nm-wafer-photo-3.jpg|Intel 300 mm wafer with 45 nm shuttle test chips | File:45nm-wafer-photo-3.jpg|Intel 300 mm wafer with 45 nm shuttle test chips | ||

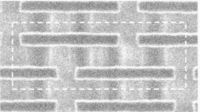

| + | File:45nm SRAM Cell.jpg|6T SRAM Bit-Cell | ||

</gallery> | </gallery> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== 45 nm Microprocessors== | == 45 nm Microprocessors== | ||

| Line 107: | Line 112: | ||

== 45 nm Microarchitectures == | == 45 nm Microarchitectures == | ||

| + | * AMD | ||

| + | ** {{amd|K10|l=arch}} | ||

| + | * IBM | ||

| + | ** {{ibm|z196|l=arch}} | ||

* Intel | * Intel | ||

| − | ** {{intel| | + | ** {{intel|Bonnell|l=arch}} |

| − | ** {{intel| | + | ** {{intel|Nehalem|l=arch}} |

| − | ** {{intel| | + | ** {{intel|Penryn|l=arch}} |

| − | * | + | * VIA Technologies |

| − | ** {{ | + | ** {{via|Isaiah|l=arch}} |

{{expand list}} | {{expand list}} | ||

| Line 125: | Line 134: | ||

== References == | == References == | ||

* Mistry, Kaizad, et al. "A 45nm logic technology with high-k+ metal gate transistors, strained silicon, 9 Cu interconnect layers, 193nm dry patterning, and 100% Pb-free packaging." Electron Devices Meeting, 2007. IEDM 2007. IEEE International. IEEE, 2007. | * Mistry, Kaizad, et al. "A 45nm logic technology with high-k+ metal gate transistors, strained silicon, 9 Cu interconnect layers, 193nm dry patterning, and 100% Pb-free packaging." Electron Devices Meeting, 2007. IEDM 2007. IEEE International. IEEE, 2007. | ||

| + | |||

| + | [[category:lithography]] | ||

Latest revision as of 20:39, 19 March 2025

The 45 nanometer (45 nm) lithography process is a full node semiconductor manufacturing process following the 55 nm process stopgap.

- Commercial integrated circuit manufacturing using 45 nm process began in 2007.

This technology was superseded by the 40 nm (HN) / 32 nm process (FN) in 2010.

Contents

Industry[edit]

In January of 2006 Intel announced that they've been able to fabricate the first fully functional SRAM chips on a 45 nm process. As a preview Intel showcased 45 nm SRAM chip (shown below) packing more than 1 billion transistors. Intel opened 3 45 nm facilities, their initial D1D facility in Oregon, Fab 32 in Arizona and Fab 28 in Israel. Intel's 45 nm process is the first time high-k + metal gate transistors was used in high-volume manufacturing process.

| Intel 45 nm Design Rules | |||

|---|---|---|---|

| Layer | Pitch | Thick | Aspect Ratio |

| Isolation | 200 nm | 200 nm | - |

| Contacted Gate |

180 nm | 60 nm | -- |

| Metal 1 | 160 nm | 144 nm | 1.8 |

| Metal 2 | 160 nm | 144 nm | 1.8 |

| Metal 3 | 160 nm | 144 nm | 1.8 |

| Metal 4 | 240 nm | 216 nm | 1.8 |

| Metal 5 | 280 nm | 252 nm | 1.8 |

| Metal 6 | 360 nm | 324 nm | 1.8 |

| Metal 7 | 560 nm | 504 nm | 1.7 |

| Metal 8 | 810 nm | 720 nm | 1.8 |

| Metal 9 | 30.5 µm | 7 µm | 0.4 |

Specifications[edit]

| Fab / Manuf |

|---|

| Process Name |

| 1st Production |

| Type |

| Wafer |

| |

| Contacted Gate Pitch |

| Interconnect Pitch (M1P) |

| SRAM bit cell (HD) |

| SRAM bit cell (LP) |

| DRAM bit cell |

| Intel | Fujitsu | TI | Toshiba / Sony / NEC |

Samsung | IBM / Toshiba / Sony / AMD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| P1266 (CPU) / P1269 (SoC) / P1266.8 (SoC) |

CS-300 | 11LP | |||||||||

| 2006 | 2008 | 2008 | 2006 | 2007 | 2007 | ||||||

| Bulk | PDSOI | ||||||||||

| 300mm | |||||||||||

| Value | 65 nm Δ | Value | 65 nm Δ | Value | 65 nm Δ | Value | 65 nm Δ | Value | 65 nm Δ | Value | 65 nm Δ |

| 180 nm | 0.82x | 190 nm | ?x | ? nm | ?x | 180 nm | ?x | ? nm | ?x | 190 nm | 0.76x |

| 160 nm | 0.76x | ? nm | ?x | ? nm | ?x | ? nm | ?x | ? nm | ?x | ? nm | ?x |

| 0.346 µm² | 0.61x | 0.225 µm² | ?x | 0.255 µm² | ?x | 0.248 µm² | ?x | 0.29 µm² | 0.54x | 0.370 µm² | 0.57x |

| 0.3816 µm² | 0.56x | 0.359 µm² | 0.53x | ||||||||

| 0.11 µm² | 0.58x | 0.067 µm² | 0.53x | ||||||||

Intel[edit]

45 nm Microprocessors[edit]

- AMD

- Freescale

- IBM

- Intel

This list is incomplete; you can help by expanding it.n Chips== This list is incomplete; you can help by expanding it.

45 nm Microarchitectures[edit]

This list is incomplete; you can help by expanding it.

Documents[edit]

References[edit]

- Mistry, Kaizad, et al. "A 45nm logic technology with high-k+ metal gate transistors, strained silicon, 9 Cu interconnect layers, 193nm dry patterning, and 100% Pb-free packaging." Electron Devices Meeting, 2007. IEDM 2007. IEEE International. IEEE, 2007.

Semiconductor lithography processes technology

Semiconductor lithography processes technology