(→Intel) |

(→Composition) |

||

| Line 169: | Line 169: | ||

=== Composition === | === Composition === | ||

[[File:intel 14nm relative density.png|left|200px]][[File:relative percentage of elements on 14nm chip.png|right|400px]] | [[File:intel 14nm relative density.png|left|200px]][[File:relative percentage of elements on 14nm chip.png|right|400px]] | ||

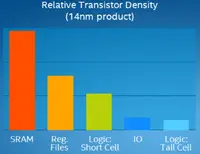

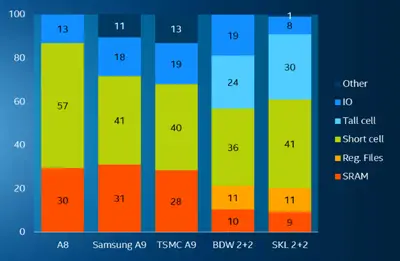

| − | It's important tot note that not all processes compete with each other. The process should cater to the products that will make use of the underlying. The composition of the actual integrated circuit also varies by manufacturer and by design due to different goals. For example, the cache on [[Apple]]'s 14 nm {{apple|A9}} (manufactured by Samsung) accounts almost 1/3 of the entire chip whereas [[Intel]]'s {{intel|Broadwell|l=arch}} cache accounts for only 10% of the entire chip. Likewise, [[Intel]]'s {{intel|Broadwell|l=arch}} and {{intel|Skylake|l=arch}} target high-performance and incorporate a large amount of higher-speed elements which are inherently sparse. Tall cells account for almost 30% Skylake's composition and less than 1% on Apple's {{apple|A8}} or {{apple|A9}}. | + | It's important tot note that not all processes compete with each other. The process should cater to the products that will make use of the underlying technology. The composition of the actual integrated circuit also varies by manufacturer and by design due to different goals. For example, the cache on [[Apple]]'s 14 nm {{apple|A9}} (manufactured by Samsung) accounts almost 1/3 of the entire chip whereas [[Intel]]'s {{intel|Broadwell|l=arch}} cache accounts for only 10% of the entire chip. Likewise, [[Intel]]'s {{intel|Broadwell|l=arch}} and {{intel|Skylake|l=arch}} target high-performance and incorporate a large amount of higher-speed elements which are inherently sparse. Tall cells account for almost 30% Skylake's composition and less than 1% on Apple's {{apple|A8}} or {{apple|A9}}. |

[[SRAM]] is by far the least dense elements of the process with sometimes up to three or four times as much less density over the logic cells that are used in the same process. | [[SRAM]] is by far the least dense elements of the process with sometimes up to three or four times as much less density over the logic cells that are used in the same process. | ||

Revision as of 17:27, 3 July 2017

The 14 nanometer (14 nm) lithography process is a semiconductor manufacturing process node serving as shrink from the 22 nm process. The term "14 nm" is simply a commercial name for a generation of a certain size and its technology, as opposed to gate length or half pitch. The 14 nm node was introduced in 2014/2015 and is currently getting replaced by the 10 nm process.

Contents

Industry

| Process Name | |

|---|---|

| 1st Production | |

| Lithography | Lithography |

| Immersion | |

| Exposure | |

| Wafer | Type |

| Size | |

| Transistor | Type |

| Voltage | |

| Fin | Pitch |

| Width | |

| Height | |

| Gate Length (Lg) | |

| Contacted Gate Pitch (CPP) | |

| Minimum Metal Pitch (MMP) | |

| SRAM bitcell | High-Perf (HP) |

| High-Density (HD) | |

| Low-Voltage (LV) | |

| DRAM bitcell | eDRAM |

| Intel | Samsung Alliance Samsung Alliance consists of a process development collaboration between Samsung and GlobalFoundries. GlobalFoundries licenses Samsung's 14nm process at Fab8, New York. |

IBM | UMC | Common Platform Alliance The Common Platform Alliance is a joint collaboration between IBM, STMicroelectronics

| |||||

|---|---|---|---|---|---|---|---|---|---|

| P1272 (CPU) / P1273 (SoC) | 14LPE 1st generation; 14 nm Low Power Early , 14LPP2nd generation; 14 nm Low Power Performance , 14LPC3rd generation; 14 nm Low Power Cost [reduced] , 14LPU4th generation; 14 nm Low Power Ultimate |

14FDSOI | |||||||

| 2014 | 2015 | ||||||||

| 193 nm | 193 nm | 193 nm | 193 nm | 193 nm | |||||

| Yes | Yes | ||||||||

| DP | |||||||||

| Bulk | Bulk | SOI | SOI | ||||||

| 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | |||||

| FinFET | FinFET | FinFET | FinFET | Planar | |||||

| 0.70 V | 0.80 V | 0.80 V | |||||||

| Value | 22 nm Δ | Value | 20 nm Δ | Value | 22 nm Δ | Value | 28 nm Δ | Value | 28 nm Δ |

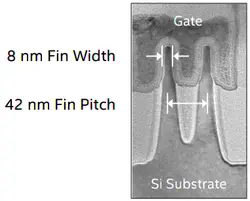

| 42 nm | 0.70x | 48 nm | N/A | 42 nm | N/A | N/A | |||

| 8 nm | 1.00x | 8 nm | 10 nm | ||||||

| 42 nm | 1.24x | ~38 nm | 25 nm | ||||||

| 20 nm | 0.77x | 30 nm | 20 nm | 0.71x | |||||

| 70 nm | 0.78x | 78 nm | 1.22x | 80 nm | 0.80x | 90 nm | 0.79x | ||

| 52 nm | 0.65x | 64 nm | 1.00x | 64 nm | 0.80x | 64 nm | 0.71x | ||

| 0.0706 µm² | 0.54x | 0.080 µm² | 0.78x | 0.0900 µm² | 0.63x | 0.090 µm² | 0.59x | ||

| 0.0499 µm² | 0.54x | 0.064 µm² | 0.79x | 0.0810 µm² | 0.81x | 0.081 µm² | 0.68x | ||

| 0.0588 µm² | 0.54x | ||||||||

| 0.0174 µm² | 0.67x | ||||||||

Composition

It's important tot note that not all processes compete with each other. The process should cater to the products that will make use of the underlying technology. The composition of the actual integrated circuit also varies by manufacturer and by design due to different goals. For example, the cache on Apple's 14 nm A9 (manufactured by Samsung) accounts almost 1/3 of the entire chip whereas Intel's Broadwell cache accounts for only 10% of the entire chip. Likewise, Intel's Broadwell and Skylake target high-performance and incorporate a large amount of higher-speed elements which are inherently sparse. Tall cells account for almost 30% Skylake's composition and less than 1% on Apple's A8 or A9.

SRAM is by far the least dense elements of the process with sometimes up to three or four times as much less density over the logic cells that are used in the same process.

Intel

- See also: Intel's Process Technology History

14 nm became Intel's 2nd generation FinFET transistors. Intel uses TiN pMOS / TiAlN nMOS as work function metals. Intel makes use of Self-Aligned Double Patterning (SADP) with 193 nm immersion lithography at critical patterning layers. Compared to all other "14 nm nodes", Intel's process is the densest and considerably so, with >1.5x raw logic density.

Intel improved on their original process with the "14nm+" offering 12% higher drive current. They later improved on that with the "14nm++" process which allows for +23-24% higher drive current for 52% less power. The 14nm++ process also appear to have slightly relaxed the CPP from 70 to 84 nm.

| Intel 14nm Design Rules | ||

|---|---|---|

| Layer | Pitch | Scale Factor |

| Fin | 42 nm | 0.70 |

| Contacted Gate Pitch | 70 nm | 0.78 |

| Metal 0 | 56 | - |

| Metal 1 | 70 | 0.78 |

| Metal 2 | 52 | 0.65 |

Samsung

This process became Samsungs' and GlobalFoundries first generation of FinFET-based transistors. Samsung uses TiN pMOS / TiAIC nMOS as work function metals.

Find models

Click to browse all 14 nm MPU models

14 nm Microprocessors

- Intel

- AMD

- Samsung

This list is incomplete; you can help by expanding it.

14 nm Microarchitectures

This list is incomplete; you can help by expanding it.

Documents

References

- Natarajan, S., et al. "A 14nm logic technology featuring 2 nd-generation FinFET, air-gapped interconnects, self-aligned double patterning and a 0.0588 µm 2 SRAM cell size." Electron Devices Meeting (IEDM), 2014 IEEE International. IEEE, 2014.

- Lin, C. H., et al. "High performance 14nm SOI FinFET CMOS technology with 0.0174 µm 2 embedded DRAM and 15 levels of Cu metallization." Electron Devices Meeting (IEDM), 2014 IEEE International. IEEE, 2014.

- Jan, C-H., et al. "A 14 nm SoC platform technology featuring 2 nd generation Tri-Gate transistors, 70 nm gate pitch, 52 nm metal pitch, and 0.0499 um 2 SRAM cells, optimized for low power, high performance and high density SoC products." VLSI Technology (VLSI Technology), 2015 Symposium on. IEEE, 2015.

- Song, Taejoong, et al. "A 14 nm FinFET 128 Mb SRAM With VMIN Enhancement Techniques for Low-Power Applications." IEEE Journal of Solid-State Circuits 50.1 (2015): 158-169.

- Weber, Olivier, et al. "14nm FDSOI technology for high speed and energy efficient applications." VLSI Technology (VLSI-Technology): Digest of Technical Papers, 2014 Symposium on. IEEE, 2014.

Semiconductor lithography processes technology

Semiconductor lithography processes technology