(→7 nm Microarchitectures) |

|||

| Line 1: | Line 1: | ||

{{lithography processes}} | {{lithography processes}} | ||

| − | The '''7 nanometer (7 nm) lithography process''' is a [[technology | + | The '''7 nanometer (7 nm) lithography process''' is a [[technology node]] semiconductor manufacturing process following the [[10 nm lithography process|10 nm process]] node. The term "7 nm" is simply a commercial name for a generation of a certain size and its technology and does not represent any geometry of a transistor. Commercial mass production of [[integrated circuit]] using 7 nm process is set to begin sometimes in 2019 or 2020. This technology will be replaced by [[5 nm lithography process|5 nm process]] around 2022. |

== Industry == | == Industry == | ||

| − | + | Only four semiconductor foundries are able to develop the advanced 7nm: [[Intel]], [[Samsung]], [[TSMC]], and [[GlobalFoundries]]. | |

| − | |||

{{future information}} | {{future information}} | ||

| Line 14: | Line 13: | ||

| process 1 name = P1276 (CPU), P1277 (SoC) | | process 1 name = P1276 (CPU), P1277 (SoC) | ||

| process 1 date = | | process 1 date = | ||

| − | | process 1 lith = | + | | process 1 lith = |

| − | | process 1 immersion = | + | | process 1 immersion = |

| − | | process 1 exposure = | + | | process 1 exposure = |

| process 1 wafer type = Bulk | | process 1 wafer type = Bulk | ||

| process 1 wafer size = 300 nm | | process 1 wafer size = 300 nm | ||

| − | | process 1 transistor = | + | | process 1 transistor = |

| process 1 volt = | | process 1 volt = | ||

| process 1 delta from = [[10 nm]] Δ | | process 1 delta from = [[10 nm]] Δ | ||

| Line 74: | Line 73: | ||

| process 2 dram = | | process 2 dram = | ||

| process 2 dram Δ = | | process 2 dram Δ = | ||

| − | <!-- | + | <!-- GlobalFoundries --> |

| − | | process 3 fab = | + | | process 3 fab = [[GlobalFoundries]] |

| process 3 name = | | process 3 name = | ||

| − | | process 3 date = | + | | process 3 date = 2019 |

| − | | process 3 lith = | + | | process 3 lith = 193 nm |

| − | | process 3 immersion = | + | | process 3 immersion = Yes |

| − | | process 3 exposure = | + | | process 3 exposure = SAQP |

| process 3 wafer type = Bulk | | process 3 wafer type = Bulk | ||

| process 3 wafer size = 300 nm | | process 3 wafer size = 300 nm | ||

| − | | process 3 transistor = | + | | process 3 transistor = FinFET |

| process 3 volt = | | process 3 volt = | ||

| process 3 delta from = [[10 nm]] Δ | | process 3 delta from = [[10 nm]] Δ | ||

| Line 94: | Line 93: | ||

| process 3 gate len = | | process 3 gate len = | ||

| process 3 gate len Δ = | | process 3 gate len Δ = | ||

| − | | process 3 cpp = | + | | process 3 cpp = |

| − | | process 3 cpp Δ = | + | | process 3 cpp Δ = |

| − | | process 3 mmp = | + | | process 3 mmp = |

| − | | process 3 mmp Δ = | + | | process 3 mmp Δ = |

| process 3 sram hp = | | process 3 sram hp = | ||

| process 3 sram hp Δ = | | process 3 sram hp Δ = | ||

| Line 106: | Line 105: | ||

| process 3 dram = | | process 3 dram = | ||

| process 3 dram Δ = | | process 3 dram Δ = | ||

| + | <!-- Samsung --> | ||

| + | | process 4 fab = [[Samsung]] | ||

| + | | process 4 name = | ||

| + | | process 4 date = 2019 | ||

| + | | process 4 lith = EUV | ||

| + | | process 4 immersion = Yes | ||

| + | | process 4 exposure = SE | ||

| + | | process 4 wafer type = Bulk | ||

| + | | process 4 wafer size = 300 nm | ||

| + | | process 4 transistor = FinFET | ||

| + | | process 4 volt = | ||

| + | | process 4 delta from = [[10 nm]] Δ | ||

| + | | process 4 fin pitch = | ||

| + | | process 4 fin pitch Δ = | ||

| + | | process 4 fin width = | ||

| + | | process 4 fin width Δ = | ||

| + | | process 4 fin height = | ||

| + | | process 4 fin height Δ = | ||

| + | | process 4 gate len = | ||

| + | | process 4 gate len Δ = | ||

| + | | process 4 cpp = | ||

| + | | process 4 cpp Δ = | ||

| + | | process 4 mmp = | ||

| + | | process 4 mmp Δ = | ||

| + | | process 4 sram hp = | ||

| + | | process 4 sram hp Δ = | ||

| + | | process 4 sram hd = | ||

| + | | process 4 sram hd Δ = | ||

| + | | process 4 sram lv = | ||

| + | | process 4 sram lv Δ = | ||

| + | | process 4 dram = | ||

| + | | process 4 dram Δ = | ||

| + | <!-- Common Platform --> | ||

| + | | process 5 fab = Common Platform<info>[[IBM]], [[Samsung]], [[GlobalFoundries]]</info> Paper | ||

| + | | process 5 name = | ||

| + | | process 5 date = | ||

| + | | process 5 lith = EUV | ||

| + | | process 5 immersion = | ||

| + | | process 5 exposure = SE | ||

| + | | process 5 wafer type = Bulk | ||

| + | | process 5 wafer size = 300 nm | ||

| + | | process 5 transistor = FinFet | ||

| + | | process 5 volt = | ||

| + | | process 5 delta from = [[10 nm]] Δ | ||

| + | | process 5 fin pitch = | ||

| + | | process 5 fin pitch Δ = | ||

| + | | process 5 fin width = | ||

| + | | process 5 fin width Δ = | ||

| + | | process 5 fin height = | ||

| + | | process 5 fin height Δ = | ||

| + | | process 5 gate len = | ||

| + | | process 5 gate len Δ = | ||

| + | | process 5 cpp = 48 nm | ||

| + | | process 5 cpp Δ = 0.75x | ||

| + | | process 5 mmp = 36 nm | ||

| + | | process 5 mmp Δ = 0.75x | ||

| + | | process 5 sram hp = | ||

| + | | process 5 sram hp Δ = | ||

| + | | process 5 sram hd = | ||

| + | | process 5 sram hd Δ = | ||

| + | | process 5 sram lv = | ||

| + | | process 5 sram lv Δ = | ||

| + | | process 5 dram = | ||

| + | | process 5 dram Δ = | ||

}} | }} | ||

| + | |||

| + | === Intel === | ||

| + | In May of 2017, Intel's Technology and Manufacturing Group Director, Mark Bohr, confirmed that Intel's 7 nm node has entered development phase and that the company's research focuses on the [[5 nm]] and [[3 nm]] nodes. Intel has been maintaining the details of their 7 nm node secrete for now. | ||

| + | |||

| + | === GlobalFoundries === | ||

| + | On May 30 2017, GlobalFoundries Senior Vice President and head of CMOS Business Unit, Gregg Bartlett, announced their updated roadmap. Instead of [[EUV]], the company will use multiple patterning 193i for their 7 nm node. The company is planning on first tape-out in the 2nd half of 2018 with mass production to begin in 2019. Bartlett noted that GF will switch to EUVL when it's ready. | ||

=== TSMC === | === TSMC === | ||

| − | + | In ISSCC 2017, the memory group at [[TSMC]] detailed their test 256 MiB SRAM chip which featured a 42.64 mm² die. The chip is manufactured on TSMC's 7nm HK-MG FinFET process using 4P4E LELELELE patterning technique. The over die is 0.34x smaller than their [[16 nm process]] version. At the same conference, [[Samsung]] detailed limited use for [[EUV]] in their 7nm node, though not much more is known. On February 8 2017 Intel announced a $7B investment in Arizona's Fab 42 which will eventually produce chips on a 7 nm process. | |

| + | |||

{| class="collapsible collapsed wikitable" | {| class="collapsible collapsed wikitable" | ||

|- | |- | ||

Revision as of 13:23, 1 June 2017

The 7 nanometer (7 nm) lithography process is a technology node semiconductor manufacturing process following the 10 nm process node. The term "7 nm" is simply a commercial name for a generation of a certain size and its technology and does not represent any geometry of a transistor. Commercial mass production of integrated circuit using 7 nm process is set to begin sometimes in 2019 or 2020. This technology will be replaced by 5 nm process around 2022.

Contents

Industry

Only four semiconductor foundries are able to develop the advanced 7nm: Intel, Samsung, TSMC, and GlobalFoundries.

| Process Name | |

|---|---|

| 1st Production | |

| Lithography | Lithography |

| Immersion | |

| Exposure | |

| Wafer | Type |

| Size | |

| Transistor | Type |

| Voltage | |

| Fin | Pitch |

| Width | |

| Height | |

| Gate Length (Lg) | |

| Contacted Gate Pitch (CPP) | |

| Minimum Metal Pitch (MMP) | |

| SRAM bitcell | High-Perf (HP) |

| High-Density (HD) | |

| Low-Voltage (LV) | |

| DRAM bitcell | eDRAM |

| Intel | TSMC | GlobalFoundries | Samsung | Common Platform Paper | |||||

|---|---|---|---|---|---|---|---|---|---|

| P1276 (CPU), P1277 (SoC) | |||||||||

| 2019 | 2019 | ||||||||

| 193 nm | 193 nm | EUV | EUV | ||||||

| Yes | Yes | Yes | |||||||

| LELELELE | SAQP | SE | SE | ||||||

| Bulk | Bulk | Bulk | Bulk | Bulk | |||||

| 300 nm | 300 nm | 300 nm | 300 nm | 300 nm | |||||

| FinFET | FinFET | FinFET | FinFet | ||||||

| Value | 10 nm Δ | Value | 10 nm Δ | Value | 10 nm Δ | Value | 10 nm Δ | Value | 10 nm Δ |

| 54 | 0.84x | 48 nm | 0.75x | ||||||

| 38 | 0.90x | 36 nm | 0.75x | ||||||

| 0.027 µm² | 0.64x | ||||||||

Intel

In May of 2017, Intel's Technology and Manufacturing Group Director, Mark Bohr, confirmed that Intel's 7 nm node has entered development phase and that the company's research focuses on the 5 nm and 3 nm nodes. Intel has been maintaining the details of their 7 nm node secrete for now.

GlobalFoundries

On May 30 2017, GlobalFoundries Senior Vice President and head of CMOS Business Unit, Gregg Bartlett, announced their updated roadmap. Instead of EUV, the company will use multiple patterning 193i for their 7 nm node. The company is planning on first tape-out in the 2nd half of 2018 with mass production to begin in 2019. Bartlett noted that GF will switch to EUVL when it's ready.

TSMC

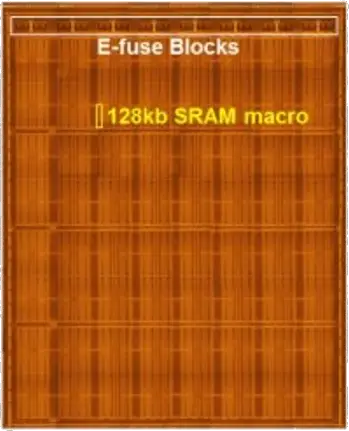

In ISSCC 2017, the memory group at TSMC detailed their test 256 MiB SRAM chip which featured a 42.64 mm² die. The chip is manufactured on TSMC's 7nm HK-MG FinFET process using 4P4E LELELELE patterning technique. The over die is 0.34x smaller than their 16 nm process version. At the same conference, Samsung detailed limited use for EUV in their 7nm node, though not much more is known. On February 8 2017 Intel announced a $7B investment in Arizona's Fab 42 which will eventually produce chips on a 7 nm process.

7 nm Microprocessors

- MediaTek

This list is incomplete; you can help by expanding it.

7 nm Microarchitectures

References

- Chang, Jonathan, et al. "12.1 A 7nm 256Mb SRAM in high-k metal-gate FinFET technology with write-assist circuitry for low-V MIN applications." Solid-State Circuits Conference (ISSCC), 2017 IEEE International. IEEE, 2017.

- Standaert, T., et al. "BEOL process integration for the 7 nm technology node." Interconnect Technology Conference/Advanced Metallization Conference (IITC/AMC), 2016 IEEE International. IEEE, 2016.

- Samsung/GlobalFoundries, IEEE International Electron Devices Meeting (IEDM) 2016

Semiconductor lithography processes technology

Semiconductor lithography processes technology