| Yield | |

| |

| Yield | |

| Yield loss | |

| Concepts | |

Yield is a quantitative measure of the quality of a semiconductor process. It is the fraction of dies on the yielding wafers that are not discarded during the manufacturing process.

Contents

Overview[edit]

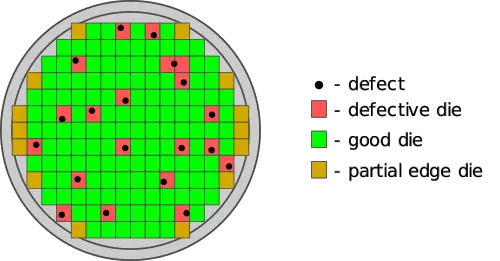

Although the goal of every fabrication process is to produce only working dies, in practice the process is never perfect and not all dies work or operate as desired within specs. Yield is a quantitative measurement of the process quality in terms of working dies.

Where,

- Ngood - number of working dies per wafer

- Ntotal - number of dies per wafer

For example, consider a process with a D0 = 0.5/cm², for dies the size of 360 mm².

There are 150 dies per wafer and around 24 defective dies per wafer, therefore the yield is .

Measuring yield[edit]

The final die yield is the compounded yield of all the independent steps that are required to produce a functional die. Those include:

- Wafer Yield (YW) - fraction of wafers that are not scrapped

- Die Yield or wafer sort yield (YD) - fraction of dies that are not scrapped

- Assembly Yield (YA) - fraction of chips that are not scrapped during the packaging stage

- Burn-in Yield (YB) - fraction of chips that pass burn-in

The overall yield is therefore Y = YW ⋅ YD ⋅ YA ⋅ YB

Yield loss[edit]

Yield loss refers to the source that affects the final yield. Those usually fall into two categories:

- Parametric Yield Loss - Dies that function but not within the desired specifications

- Catastrophic Yield Loss - Dies that do not function due to a defect

During a new process technology bring-up, yield loss can be very high (< 40% yield). The process of identifying yield losses, quantifying them, and improving them is referred to as yield learning.

Yield modeling[edit]

| This section is empty; you can help add the missing info by editing this page. |

Design for Manufacturability[edit]

| This section is empty; you can help add the missing info by editing this page. |