m |

(→See also) |

||

| Line 19: | Line 19: | ||

== See also == | == See also == | ||

| + | * [[Transistor density]] | ||

* [[CPP x FP]] | * [[CPP x FP]] | ||

* [[CPP x MxP]] | * [[CPP x MxP]] | ||

* [[CPP x MxP x Tracks]] | * [[CPP x MxP x Tracks]] | ||

Revision as of 23:50, 9 January 2019

MTr/mm² (mega-transistor per squared millimeter) is a transistor density unit that serves as a figure of merit in quantifying a process node. The metric makes use of a weighted system consisting of two typical standard cells found in most libraries - a very small NAND2 cell and a very large SFF cell.

Overview

The metric was proposed by Mark Bohr, Intel's director of process architecture and integration, in 2017. Bohr stated the metric is actually a resurrection of a similar metric that had been abandoned in the past. The metric attempts to take into account second-order design rules that the simpler density metrics such as CPP x MxP and CPP x MxP x Tracks cannot capture because they do not represent a typical standard cell. It should be noted that the metric explicitly excludes SRAM cell sizes because of the large variance in SRAM-to-logic ratio between popular chips. Furthermore, the metal pitch does not play a role in limiting SRAM as it does with other standard cells. Therefore, SRAM cell sizes should be reported separately alongside the MTr/mm² unit.

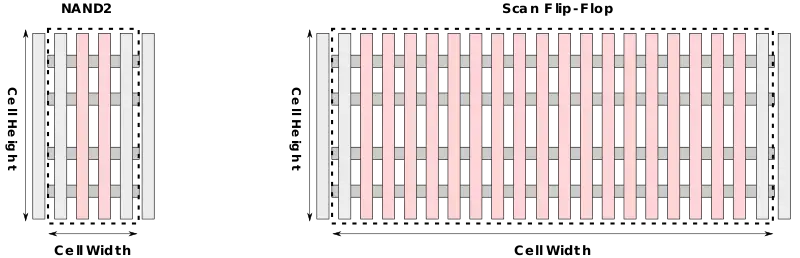

Two cells that are found in every standard library are used: a very small 2-input NAND cell consisting of just four transistors and a very large scan flip-flop cell. The NAND2 is weighted as 0.6 while the SFF is weighted as 0.4.

Example

Intel's 10 nm process consists of a minimum metal pitch of 36nm with 8 diffusion lines for a cell height of 272 nanometers. Additionally, the process has a poly pitch of 54 nm and cells on Intel's 10 nm use a single dummy gate. For 0.6 NAND2 + 0.4 SFF, Intel's 10nm has a density of 100.76 MTr/mm² along with a high-density 6T SRAM measuring 0.0312 µm². Note that Intel itself reported their 10nm at 100.8 MTr/mm².

Intel's 22 nm process (2012) had 16.5 MTr/mm², 14 nm process (2014) had 44.67 MTr/mm², and 14++ nm process had 37.22 MTr/mm².