(→Die size) |

(→Die size) |

||

| Line 21: | Line 21: | ||

|- style="vertical-align: top;" | |- style="vertical-align: top;" | ||

| | | | ||

| + | * 826 mm² (GA100) | ||

* 815 mm² (GV100) | * 815 mm² (GV100) | ||

* 754 mm² (TU102) | * 754 mm² (TU102) | ||

Revision as of 02:36, 1 June 2020

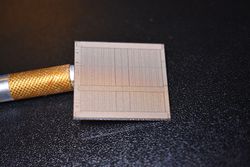

A die is the actual bare IC chip and is the final product of the fabrication process. It is the individual chip made following the singulation of a wafer. Dies typically undergo packaging before being sold to the customer as a final product.

Contents

Overview

The die is the final product of the fabrication process. A fully processed wafer will under singulation following probing. Depending on the application, the die may be shipped to an assembly/packaging plant where it will undergo encapsulation, producing the final chip that ships to customers.

Known good die

- Main article: Known Good Die (KGD)

A known good die is a special type of bare die that underwent additional testing and screening post-singulation. KGD testing ensures the die meets the required specification prior to getting packaged. KGDs are especially important in multi-chip packages where multiple dies in a single package must function correctly to produce the required product.

Die size

- Main article: die size

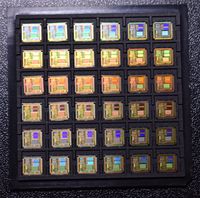

Die size refers to the length and width of the die. Since the die size and shape determines the total number of dies that may be realized from a single wafer, the die size is a strong indicator of cost.

| Select Large Dies | |||

|---|---|---|---|

| GPU | Server | Desktop | Mobile |

|

|

|

|

This list is incomplete; you can help by expanding it.