(Created page with "'''Flip Chip Ball Grid Array''' ('''fcBGA''' or simply ''Flip-chip BGA'') is a mid-cost, high-performance, semiconductor packaging solution that util...") |

|||

| Line 1: | Line 1: | ||

'''Flip Chip Ball Grid Array''' ('''fcBGA''' or simply ''Flip-chip BGA'') is a mid-cost, high-performance, [[Semiconductor package|semiconductor packaging]] solution that utilizes the [[controlled collapse chip connection]] technology, also known as [[flip chip]], for its [[die]] to [[substrate]] interconnection. fcBGA provides the design flexibility for much higher signal density and functionality into a smaller die and packaging footprint. fcBGA packaging is attractive where performance is more important than cost. Flip-chip BGA packages can be mounted using standard [[printed circuit board]]s and can be replaced using existing standard repair practices. | '''Flip Chip Ball Grid Array''' ('''fcBGA''' or simply ''Flip-chip BGA'') is a mid-cost, high-performance, [[Semiconductor package|semiconductor packaging]] solution that utilizes the [[controlled collapse chip connection]] technology, also known as [[flip chip]], for its [[die]] to [[substrate]] interconnection. fcBGA provides the design flexibility for much higher signal density and functionality into a smaller die and packaging footprint. fcBGA packaging is attractive where performance is more important than cost. Flip-chip BGA packages can be mounted using standard [[printed circuit board]]s and can be replaced using existing standard repair practices. | ||

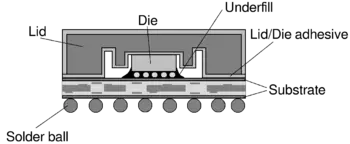

| + | [[File:Typical Flip Chip BGA Package (Cross-Sectional View).png|thumb|350px|right|Typical [[Flip Chip BGA]] Package (Cross-Sectional View)]] | ||

Today most flip-chip BGA packages are assembled on two-metal layer or multi-layered, high density ceramic substrates or organic laminate. Additionally fcBGA packages are often offered in bare die, flat lid, and full lid configuration. They are used extensively [[Application-specific integrated circuit|ASIC]], [[Digital signal processor|DSP]], and various other high performance applications. | Today most flip-chip BGA packages are assembled on two-metal layer or multi-layered, high density ceramic substrates or organic laminate. Additionally fcBGA packages are often offered in bare die, flat lid, and full lid configuration. They are used extensively [[Application-specific integrated circuit|ASIC]], [[Digital signal processor|DSP]], and various other high performance applications. | ||

| − | fcBGA packages is used in all main semiconductor manufacturers such as in the latest [[Intel]]'s [[Core i7]], [[Texas Instruments]] custom [[ASIC]]s. | + | fcBGA packages is used in all main semiconductor manufacturers such as in the latest [[Intel]]'s [[Core i7]], [[Texas Instruments]] custom [[ASIC]]s, and [[Freescale]] processors. |

Revision as of 02:35, 17 December 2013

Flip Chip Ball Grid Array (fcBGA or simply Flip-chip BGA) is a mid-cost, high-performance, semiconductor packaging solution that utilizes the controlled collapse chip connection technology, also known as flip chip, for its die to substrate interconnection. fcBGA provides the design flexibility for much higher signal density and functionality into a smaller die and packaging footprint. fcBGA packaging is attractive where performance is more important than cost. Flip-chip BGA packages can be mounted using standard printed circuit boards and can be replaced using existing standard repair practices.

Today most flip-chip BGA packages are assembled on two-metal layer or multi-layered, high density ceramic substrates or organic laminate. Additionally fcBGA packages are often offered in bare die, flat lid, and full lid configuration. They are used extensively ASIC, DSP, and various other high performance applications.

fcBGA packages is used in all main semiconductor manufacturers such as in the latest Intel's Core i7, Texas Instruments custom ASICs, and Freescale processors.