| Packaging | |

| |

| Technologies | |

| Concepts | |

| Single-Row | |

| Dual-Row | |

| Quad-Row | |

| Grid Array | |

| 2.5D IC | |

| 3D IC | |

Chip-on-Wafer-on-Substrate (CoWoS) is a two-point-five dimensional integrated circuit (2.5D IC) through-silicon via (TSV) interposer-based packaging technology designed by TSMC for high-performance applications.

Overview

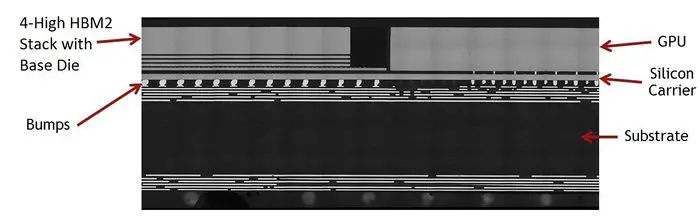

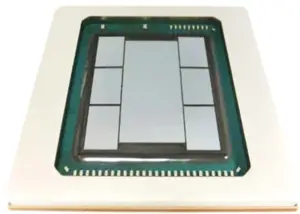

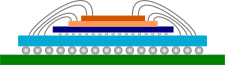

CoWoS is a 2.5D wafer-level multi-chip packaging technology that incorporates multiple dies side-by-side on a silicon interposer in order to achieve better interconnect density and performance. Individual chips are bonded through micro-bumps on a silicon interposer forming a chip-on-wafer (CoW). The CoW is then subsequently thinned such that the TSV perforations are exposed. This is followed C4 bumps formation and singulation. A CoWoS package is completed through bonding to a package substrate.

Versions

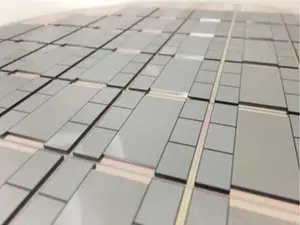

TSMC has introduced a number of versions since they first introduced the technology in 2012.

CoWoS-1

First-generation CoWoS were primarily used for large FPGAs. CoWoS-1 had an interposer die area of up to ~800 mm², very close to reticle limit

CoWoS-2

Second-generation of CoWoS increased the interposer size considerably through mask stitching. Originally qualified for 1200 mm², TSMC has since increased the interposer size to 1,700 mm². Those large packages are referred to as CoWoS-XL2.

Examples

Nvidia Pascal P100:

- 16 nm SoC chip + 4 HBM2 (16 GB)

- 1200 mm² interposer

- 300 W TDP

- 150B transistors (15.3B SoC)

NEC Sx-Aurora:

- 16 nm process

- 60 mm x 60 mm (3600 mm²) package

- 32.5 mm x 38 mm (1235 mm²) interposer

- 15mm x 33mm (495 mm²) logic

- 300 W TDP