From WikiChip

Difference between revisions of "intel/microarchitectures/p6"

(→Process Technology) |

|||

| Line 25: | Line 25: | ||

== Process Technology == | == Process Technology == | ||

| − | P6 was manufactured on [[0.35 µm process]] initially and | + | P6 was manufactured on the [[0.35 µm process]] initially and later enjoyed a process shrink down to [[0.25 µm]], allowing for considerably lower voltage and higher clock speed at a smaller silicon die area. The shrink introduced a 5th metal layer which further reduced RC delay and die area. Intel claimed the channel area was reduced by 50% with the introduction of the 5th layer. The 5th layer also enabled Intel to support C4 packaging. |

{| class="wikitable" | {| class="wikitable" | ||

Revision as of 22:29, 1 August 2017

| Edit Values | |

| P6 µarch | |

| General Info | |

| Arch Type | CPU |

| Designer | Intel |

| Manufacturer | Intel |

| Introduction | October, 1995 |

| Phase-out | December, 2000 |

| Process | 350 nm, 250 nm |

| Succession | |

P6 was the microarchitecture for Intel's for desktops and servers as a successor to P5. Introduced in 1995 and continued until 2000, P6 was fabricated using 350 nm and 250 nm processes. P6 was obsoleted by NetBurst in late 2000.

Contents

Codenames

| This section is empty; you can help add the missing info by editing this page. |

Process Technology

P6 was manufactured on the 0.35 µm process initially and later enjoyed a process shrink down to 0.25 µm, allowing for considerably lower voltage and higher clock speed at a smaller silicon die area. The shrink introduced a 5th metal layer which further reduced RC delay and die area. Intel claimed the channel area was reduced by 50% with the introduction of the 5th layer. The 5th layer also enabled Intel to support C4 packaging.

| 0.35 µm | 0.25 µm | Δ | |

|---|---|---|---|

| Contacted Gate Pitch | 550 nm | 500 nm | 0.91x |

| Interconnect Pitch | 880 nm | 640 nm | 0.73x |

Compiler support

| This section is empty; you can help add the missing info by editing this page. |

Architecture

| This section is empty; you can help add the missing info by editing this page. |

Die Shot

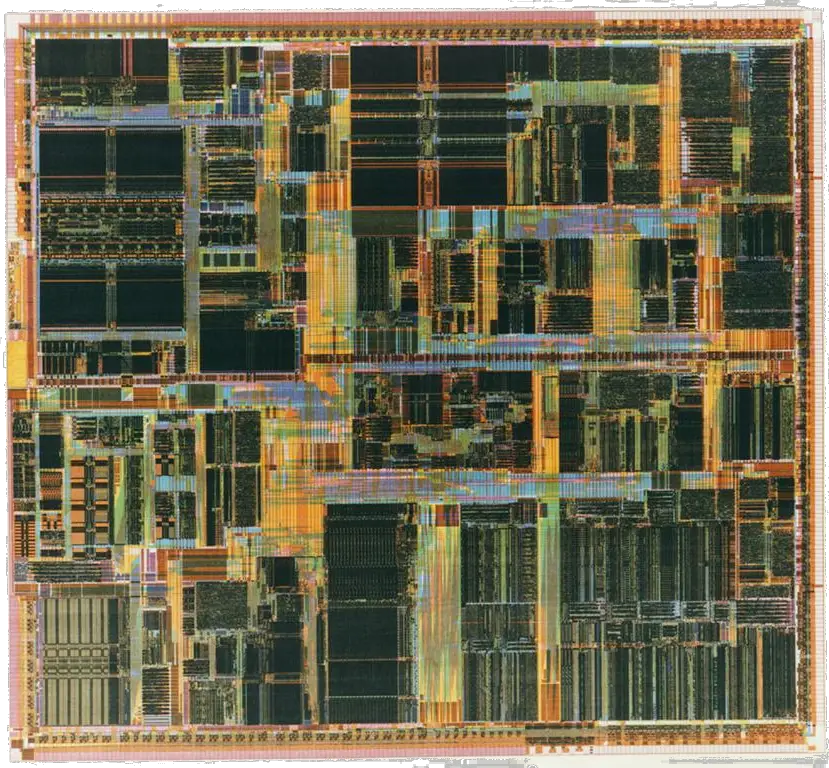

Klamath

- 280 nm process CMOS

- 4 metal layers

- 7,500,000 transistors

- 13.3 mm x 14.6 mm

- 194.8 mm² die size

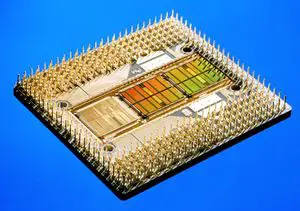

- 540-pin BGA (Ball Grid Array)

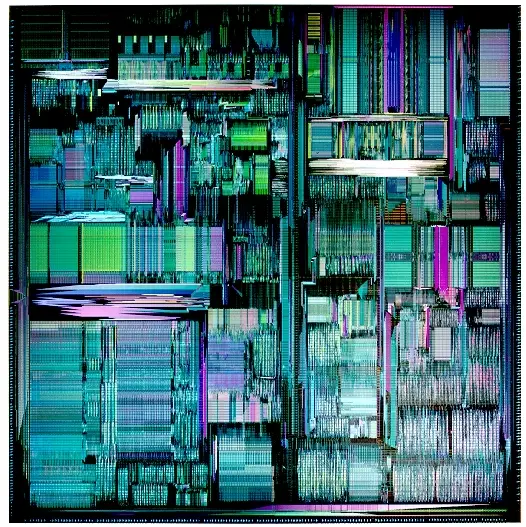

Pentium Pro

- 0.35 µm process

- 5,500,000 transistors

References

- Schutz, J., and R. Wallace. "A 450 MHz IA32 P6 family microprocessor." Solid-State Circuits Conference, 1998. Digest of Technical Papers. 1998 IEEE International. IEEE, 1998.

- Brand, Adam, et al. "Intel’s 0.25 micron, 2.0 volts logic process technology." Intel Technology Journal Q 3 (1998): 1998.

- Integrated Circuit Engineering (ICE) Corporation. "Construction Analysis Intel 266MHz 32-Bit Pentium II (Klamath) Processor"; Shared Construction Analysis (SCA) 9706-542.

Documents

- Intel Architecture Optimization Manual, Document 242816-003; 1997

Facts about "P6 - Microarchitectures - Intel"

| codename | P6 + |

| designer | Intel + |

| first launched | October 1995 + |

| full page name | intel/microarchitectures/p6 + |

| instance of | microarchitecture + |

| instruction set architecture | x86-16 + and x86-32 + |

| manufacturer | Intel + |

| microarchitecture type | CPU + |

| name | P6 + |

| phase-out | December 2000 + |

| process | 350 nm (0.35 μm, 3.5e-4 mm) + and 250 nm (0.25 μm, 2.5e-4 mm) + |