(→Die size) |

|||

| Line 6: | Line 6: | ||

== Overview == | == Overview == | ||

The die is the final product of the [[fabrication process]]. A fully processed wafer will under [[singulation]] following [[wafer probing|probing]]. Depending on the application, the die may be shipped to an assembly/packaging plant where it will undergo [[encapsulation]], producing the final chip that ships to customers. | The die is the final product of the [[fabrication process]]. A fully processed wafer will under [[singulation]] following [[wafer probing|probing]]. Depending on the application, the die may be shipped to an assembly/packaging plant where it will undergo [[encapsulation]], producing the final chip that ships to customers. | ||

| + | |||

| + | === Known good die === | ||

| + | {{main|known good die|l1=Known Good Die (KGD)}} | ||

| + | A '''[[known good die]]''' is a special type of bare die that underwent additional testing and screening post-[[singulation]]. KGD testing ensures the die meets the required specification prior to getting packaged. KGDs are especially important in [[multi-chip packages]] where multiple dies in a single package must function correctly to produce the required product. | ||

== Die size == | == Die size == | ||

Revision as of 13:13, 11 May 2020

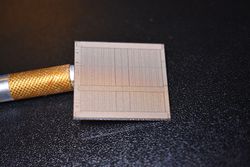

A die is the actual bare IC chip and is the final product of the fabrication process. It is the individual chip made following the singulation of a wafer. Dies typically undergo packaging before being sold to the customer as a final product.

Contents

Overview

The die is the final product of the fabrication process. A fully processed wafer will under singulation following probing. Depending on the application, the die may be shipped to an assembly/packaging plant where it will undergo encapsulation, producing the final chip that ships to customers.

Known good die

- Main article: Known Good Die (KGD)

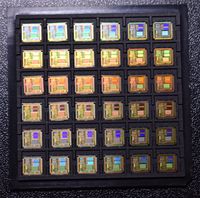

A known good die is a special type of bare die that underwent additional testing and screening post-singulation. KGD testing ensures the die meets the required specification prior to getting packaged. KGDs are especially important in multi-chip packages where multiple dies in a single package must function correctly to produce the required product.

Die size

Die size refers to the length and width of the die. Since the die size and shape determines the total number of dies that may be realized from a single wafer, the die size is a strong indicator of cost.

| Select Large Dies | |||

|---|---|---|---|

| GPU | Server | Desktop | Mobile |

|

|

|

|

This list is incomplete; you can help by expanding it.